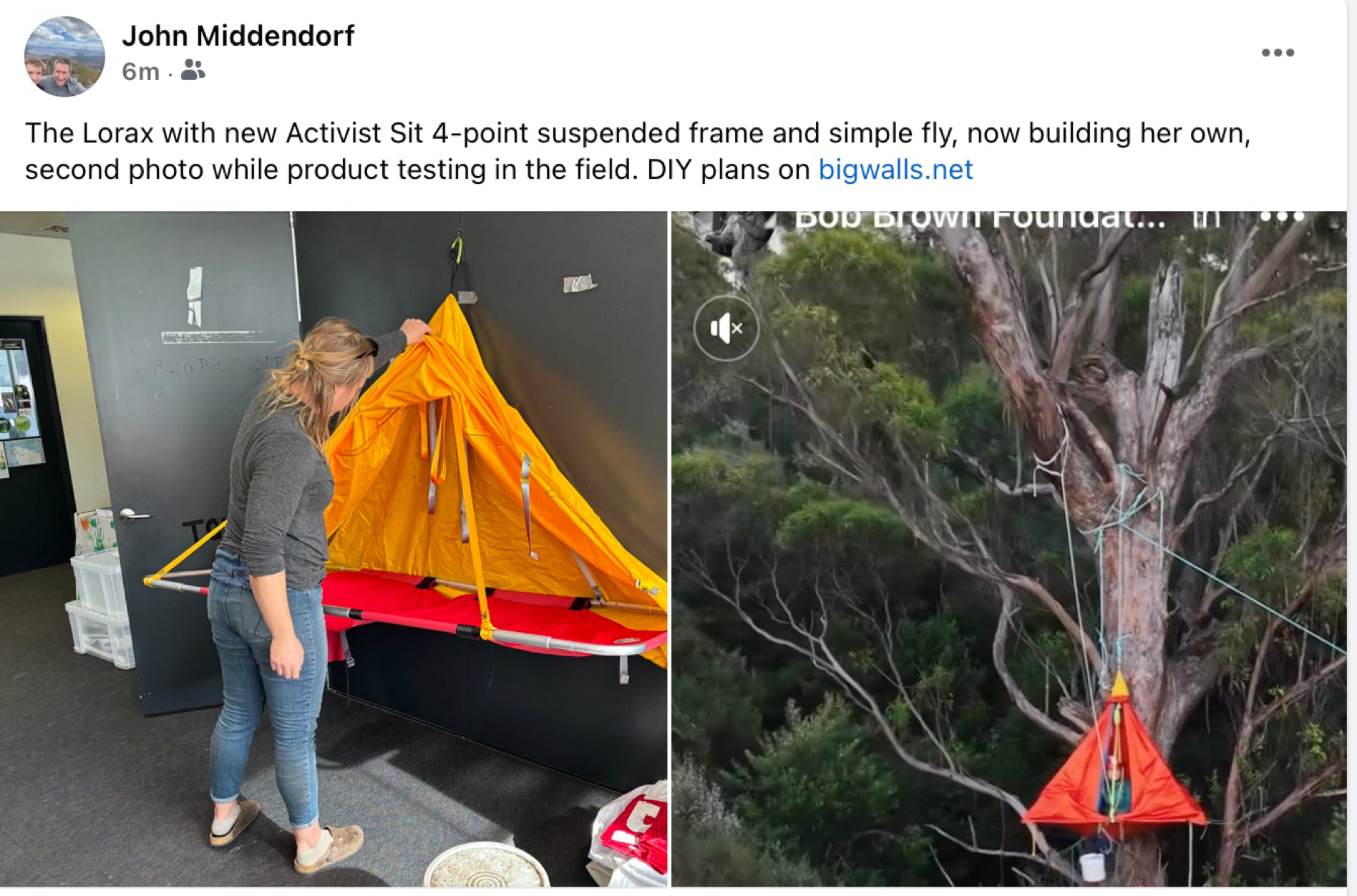

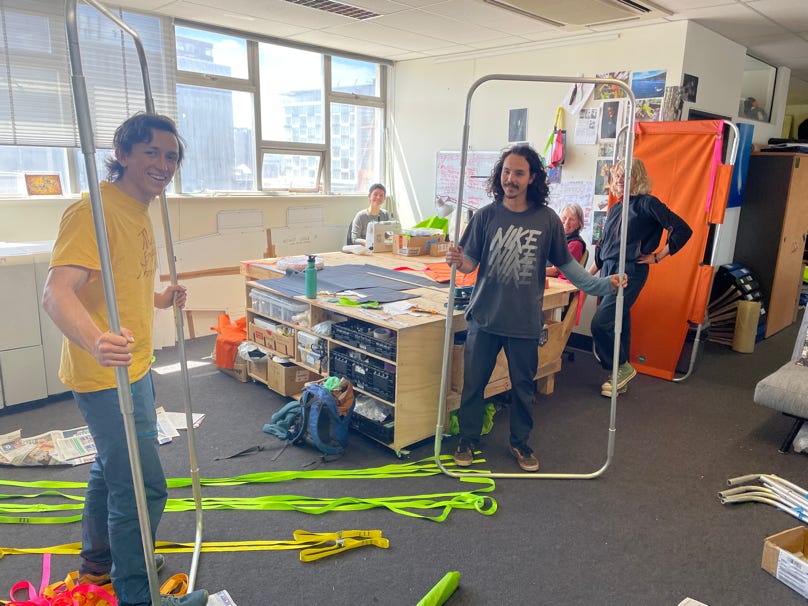

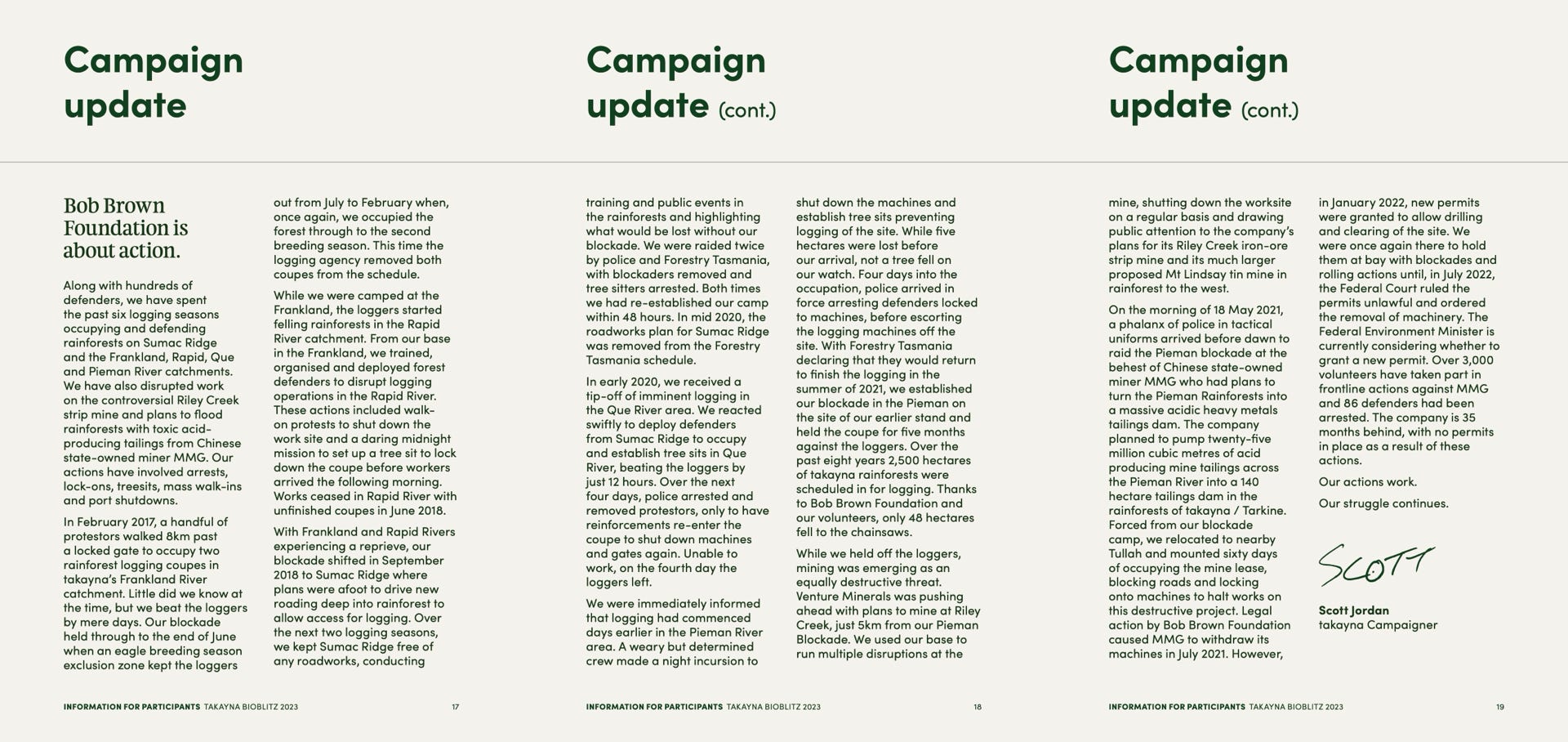

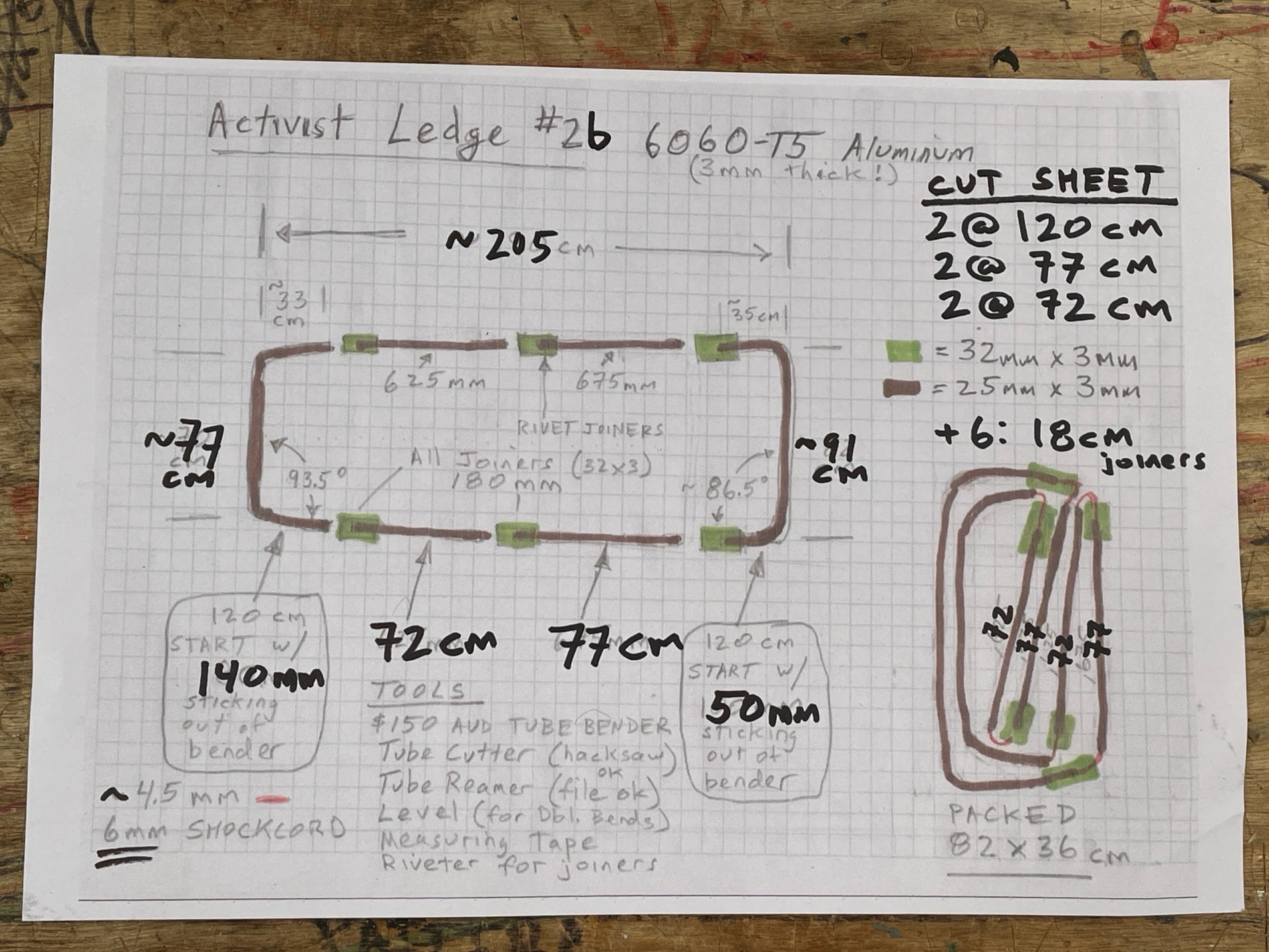

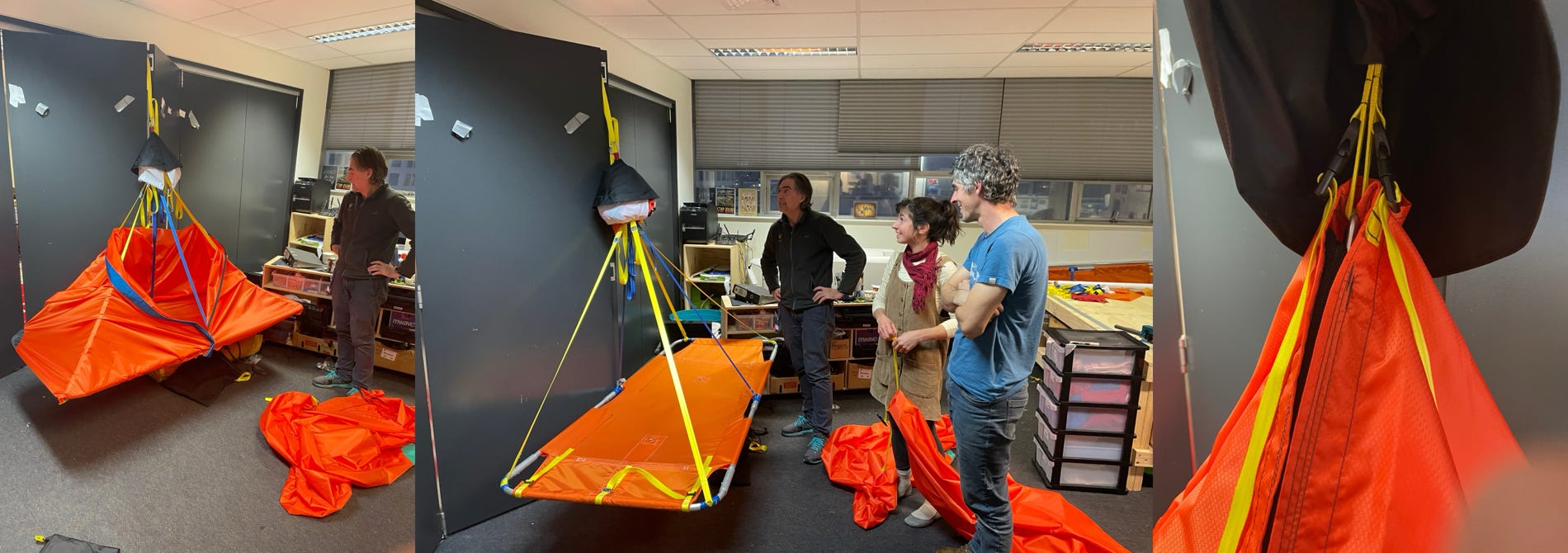

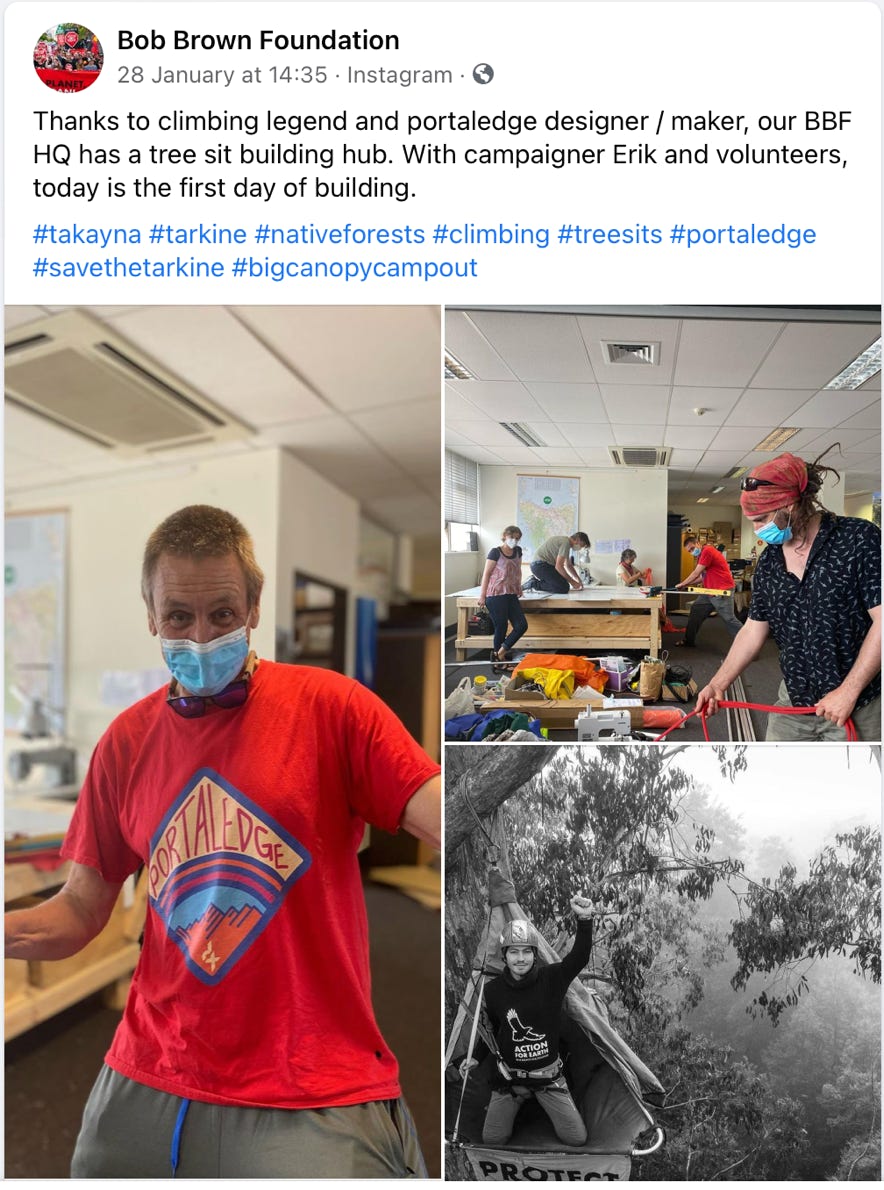

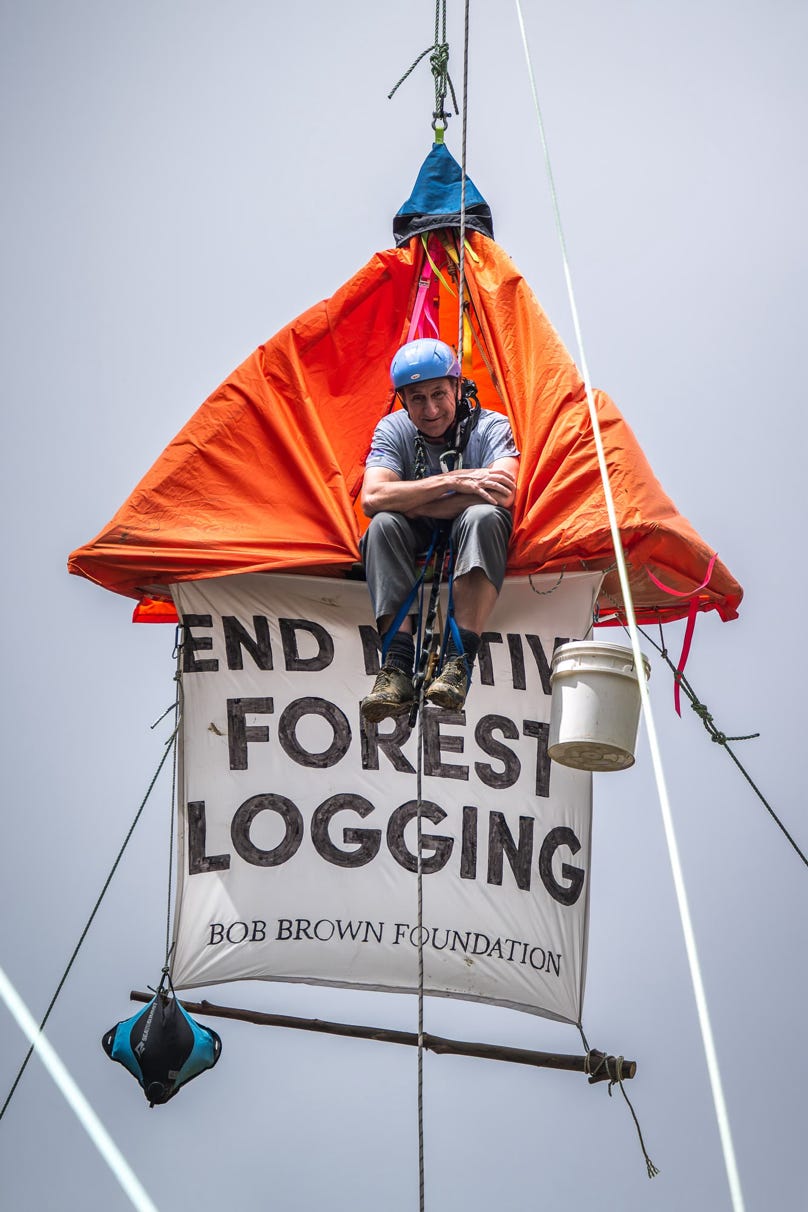

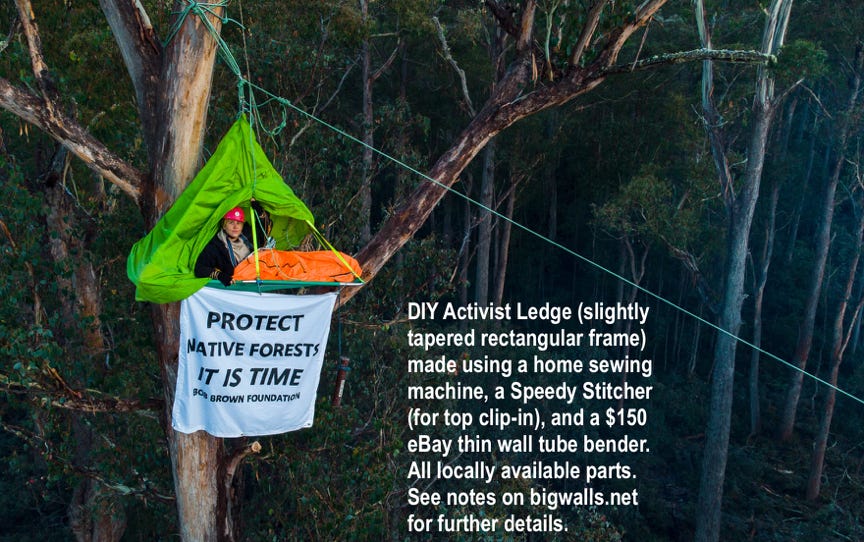

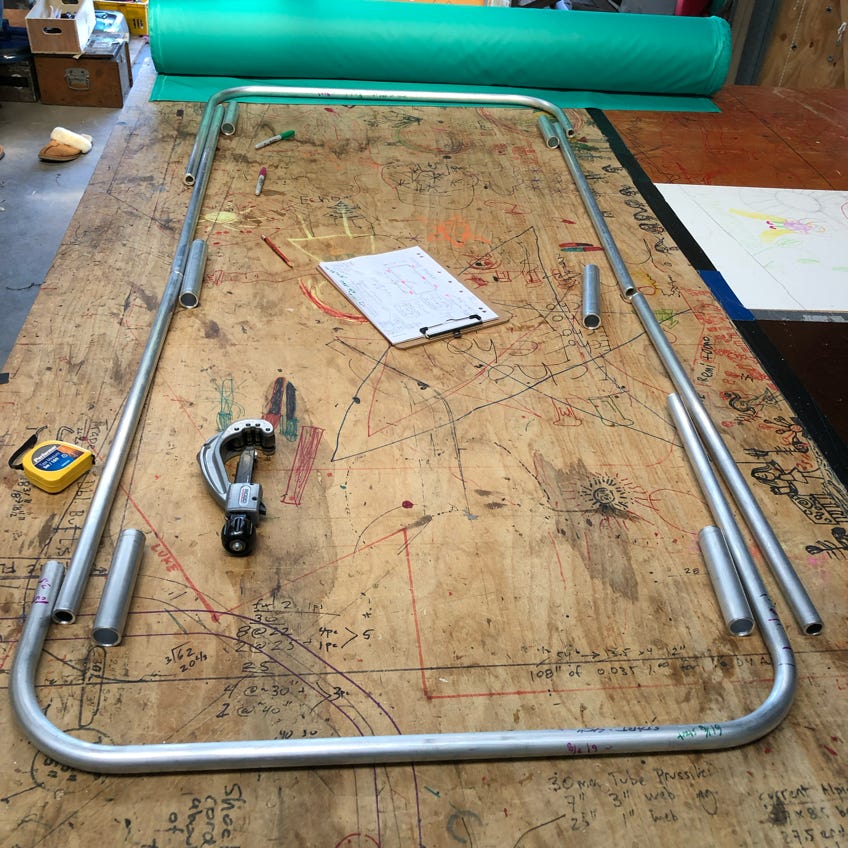

DIY Activist Ledge--a simple portaledge design using locally supplied aluminum tube.

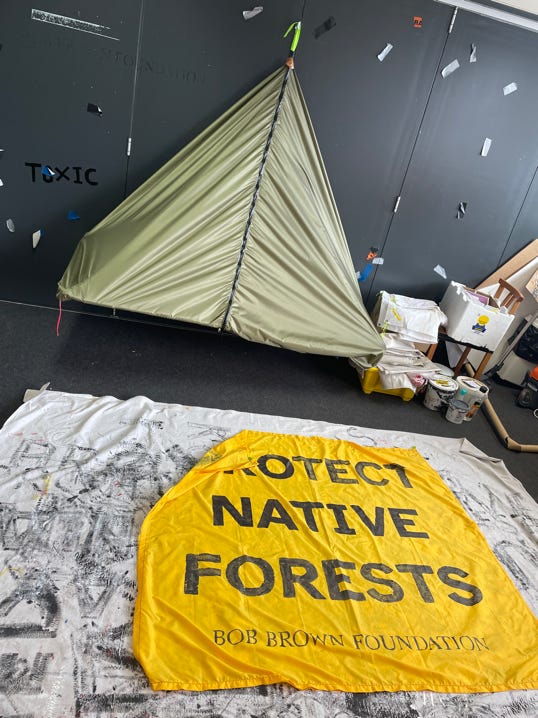

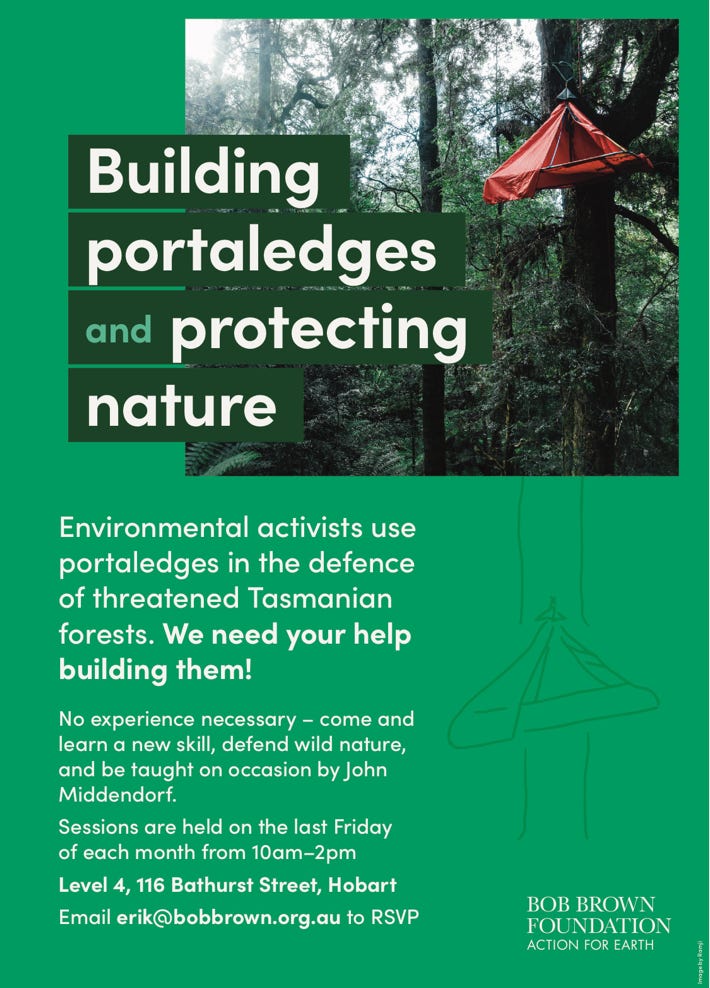

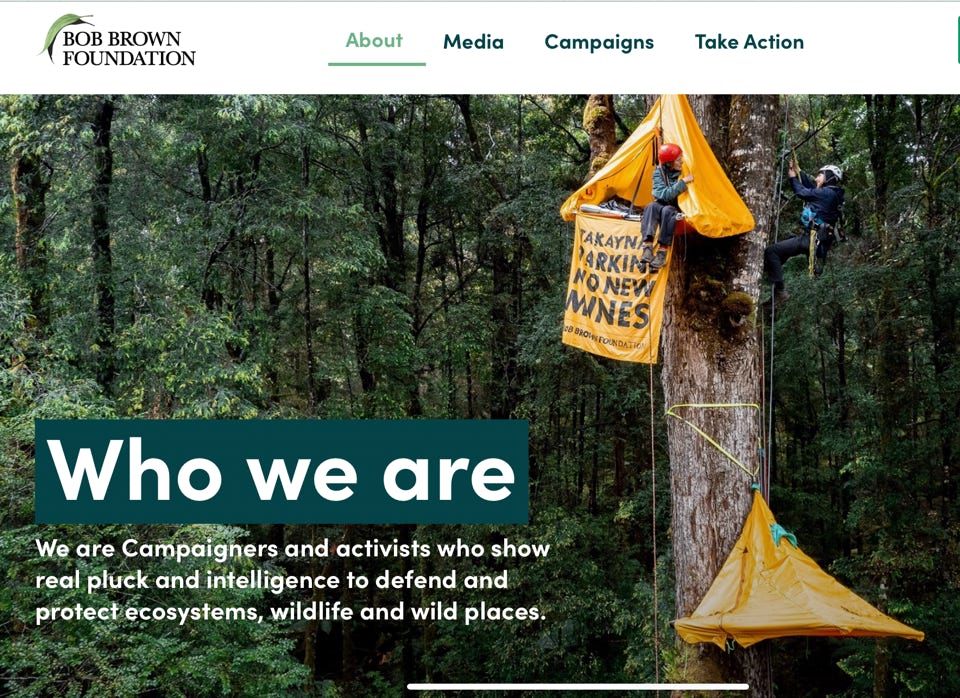

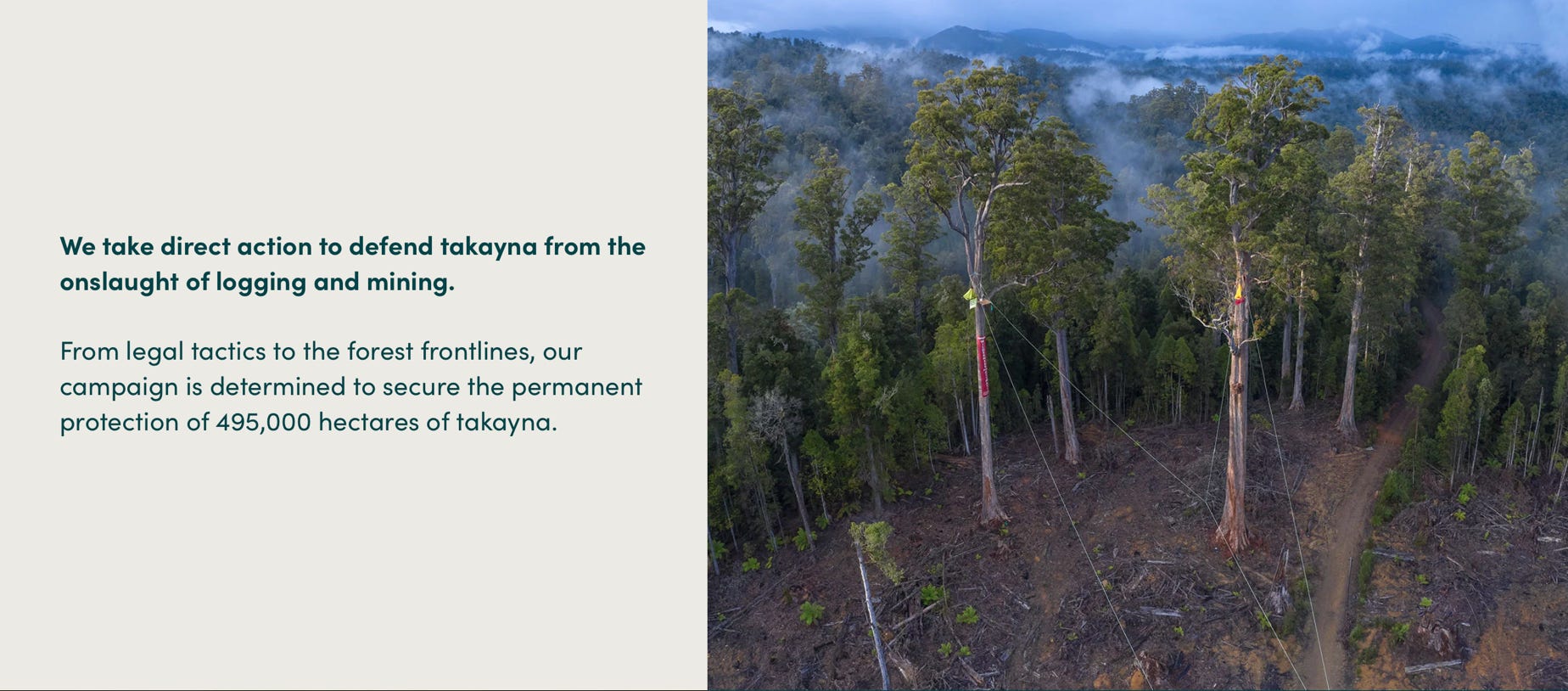

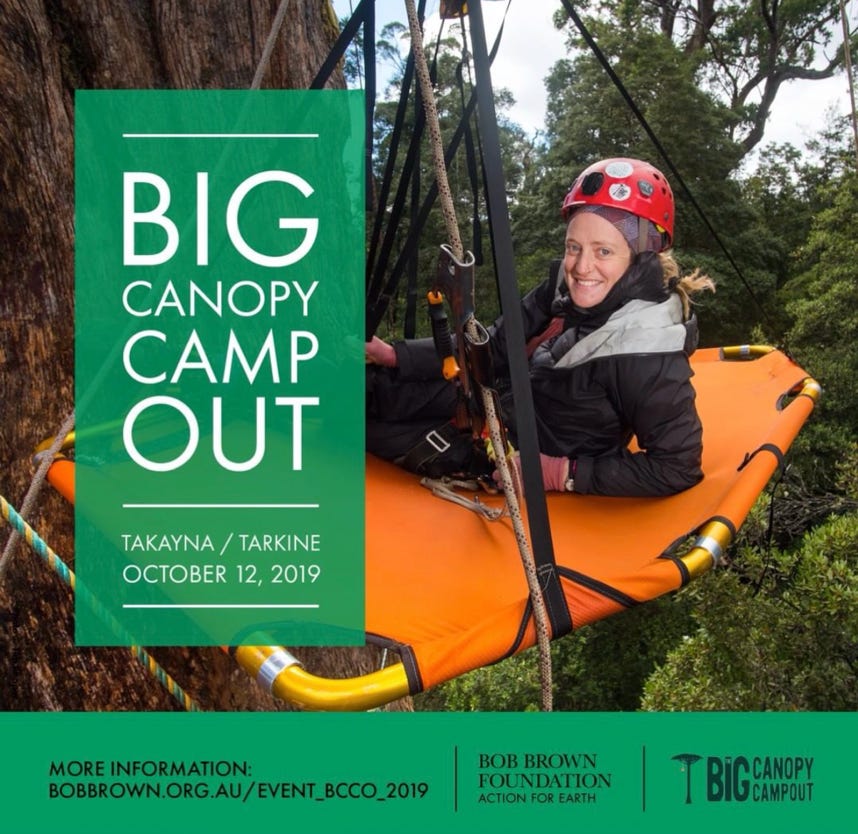

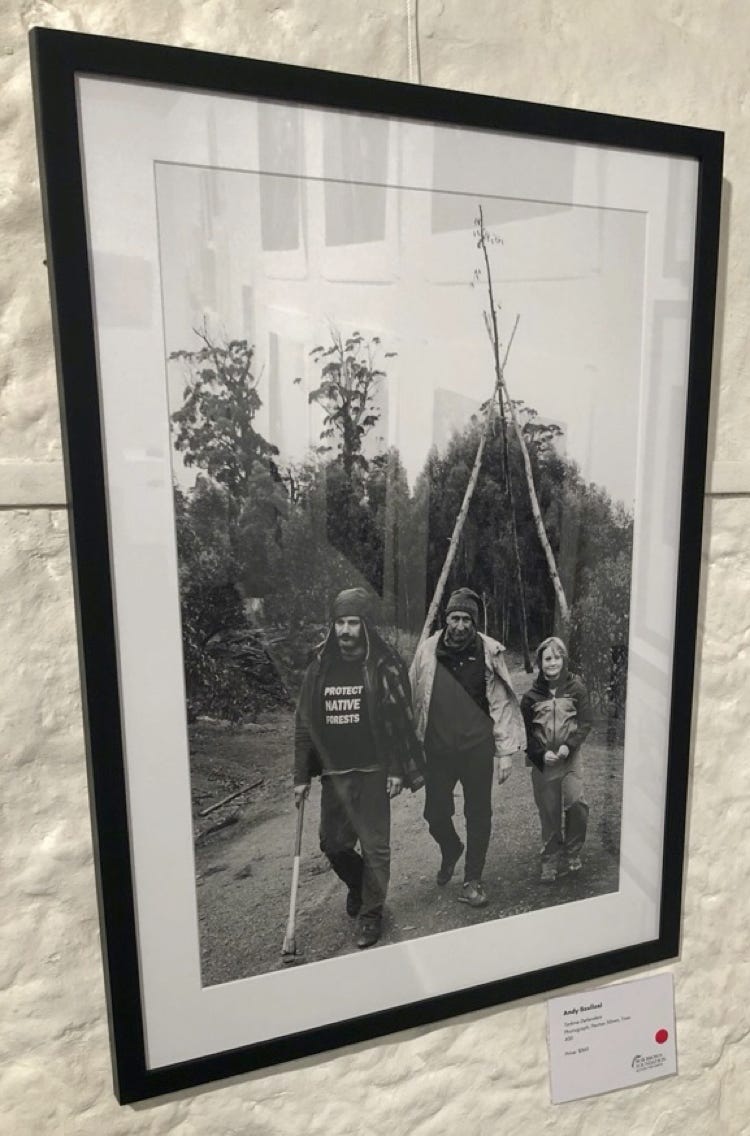

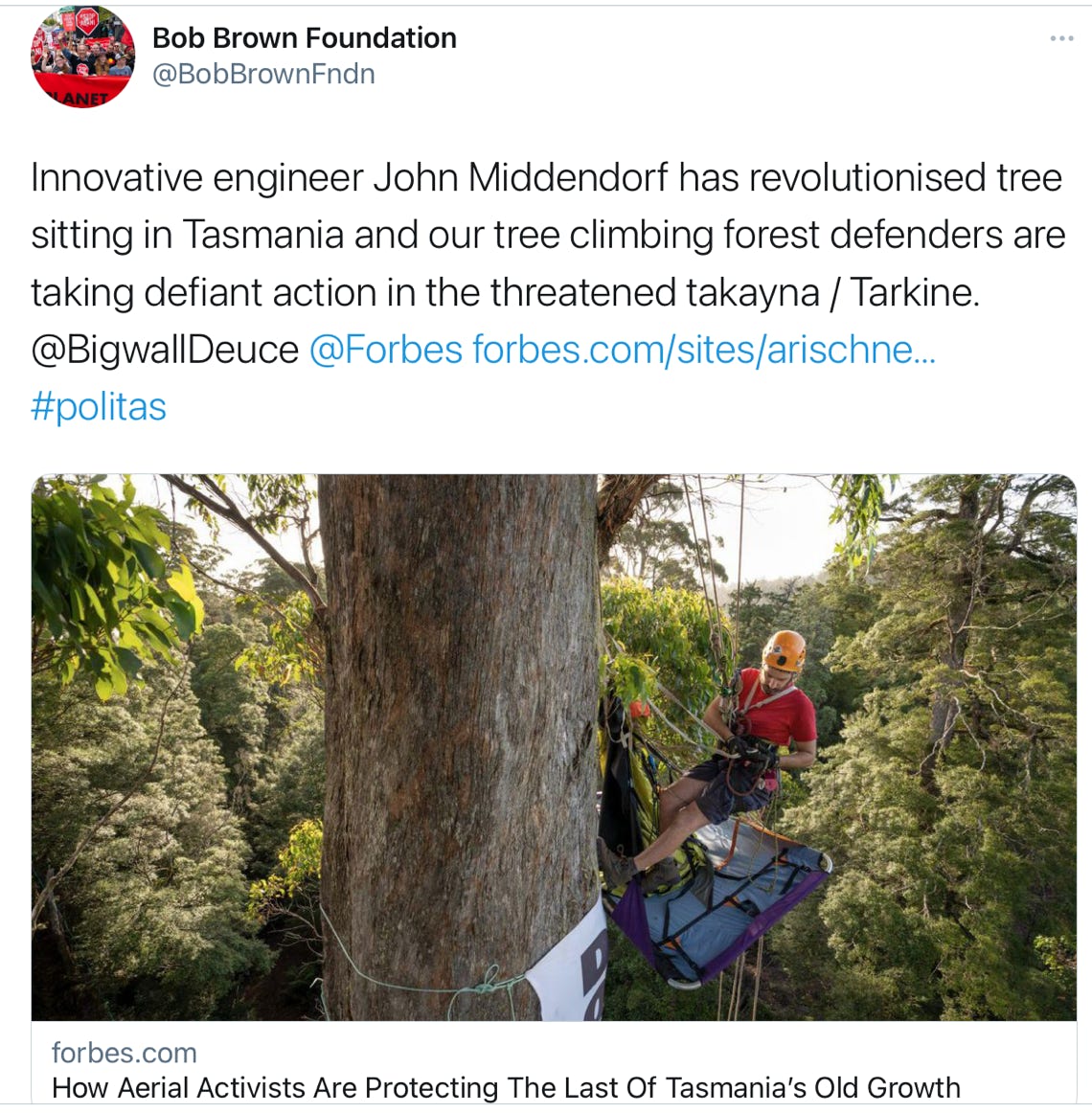

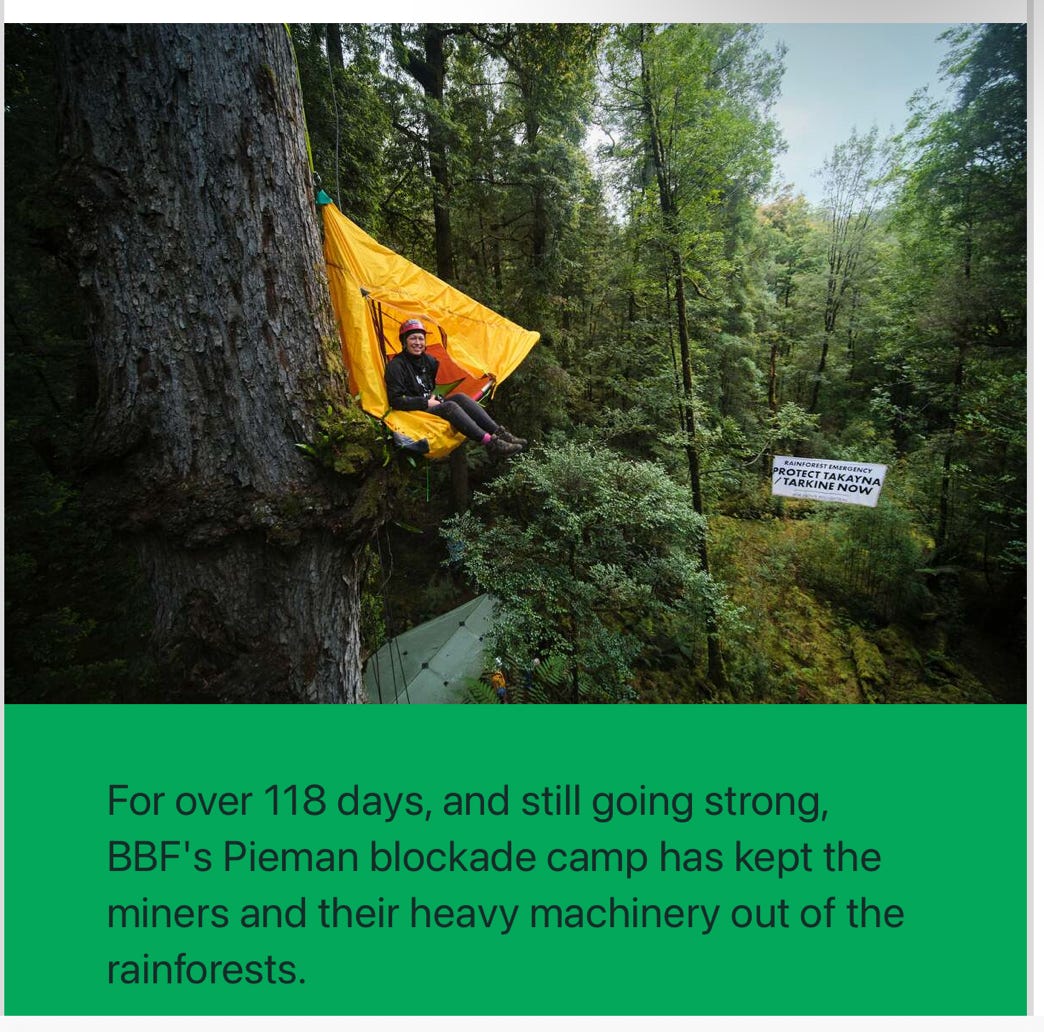

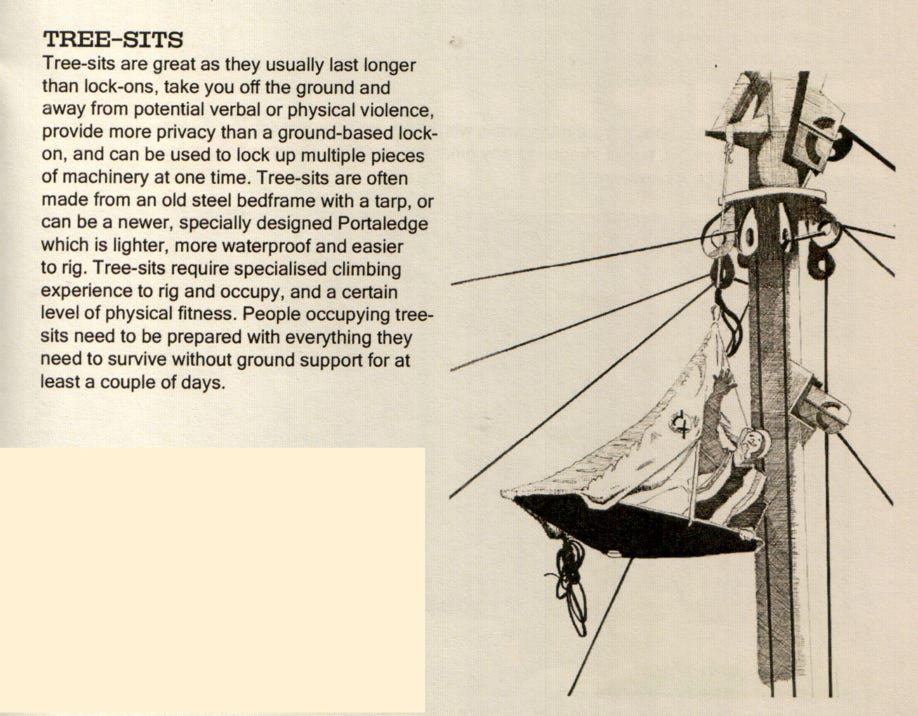

This frame inspired by the need to create easy (and inexpensive) DIY activist "sits" for aerial activists, namely in the threatened Tarkine Rainforest in Tasmania. Why protect the last remaining old growth forests in Tasmania?: TARKINE SLIDE SHOW.

WARNING: Build and use at your own risk. Always stay tied in short to the main anchor when testing or using any single-point hanging portaledge!

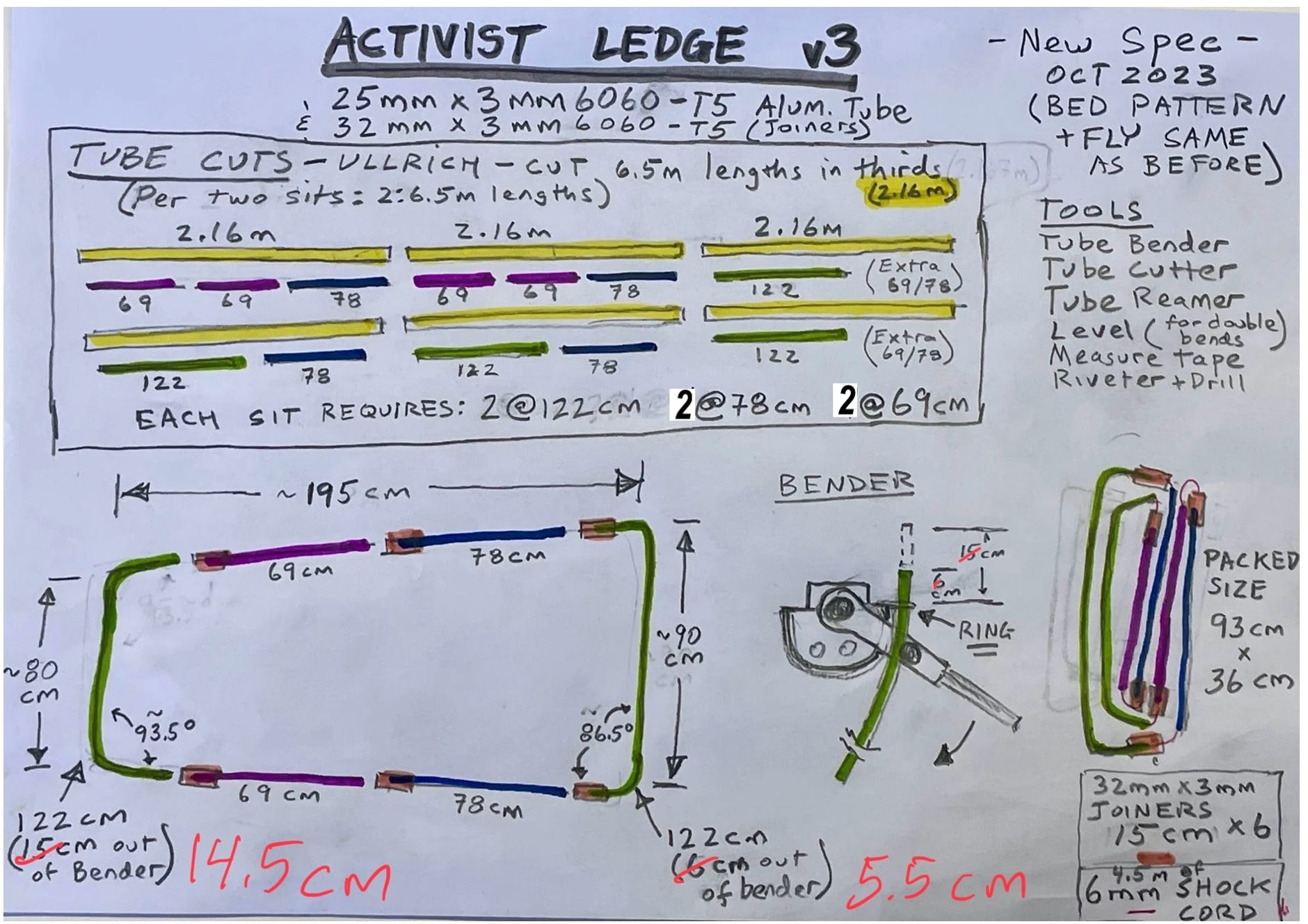

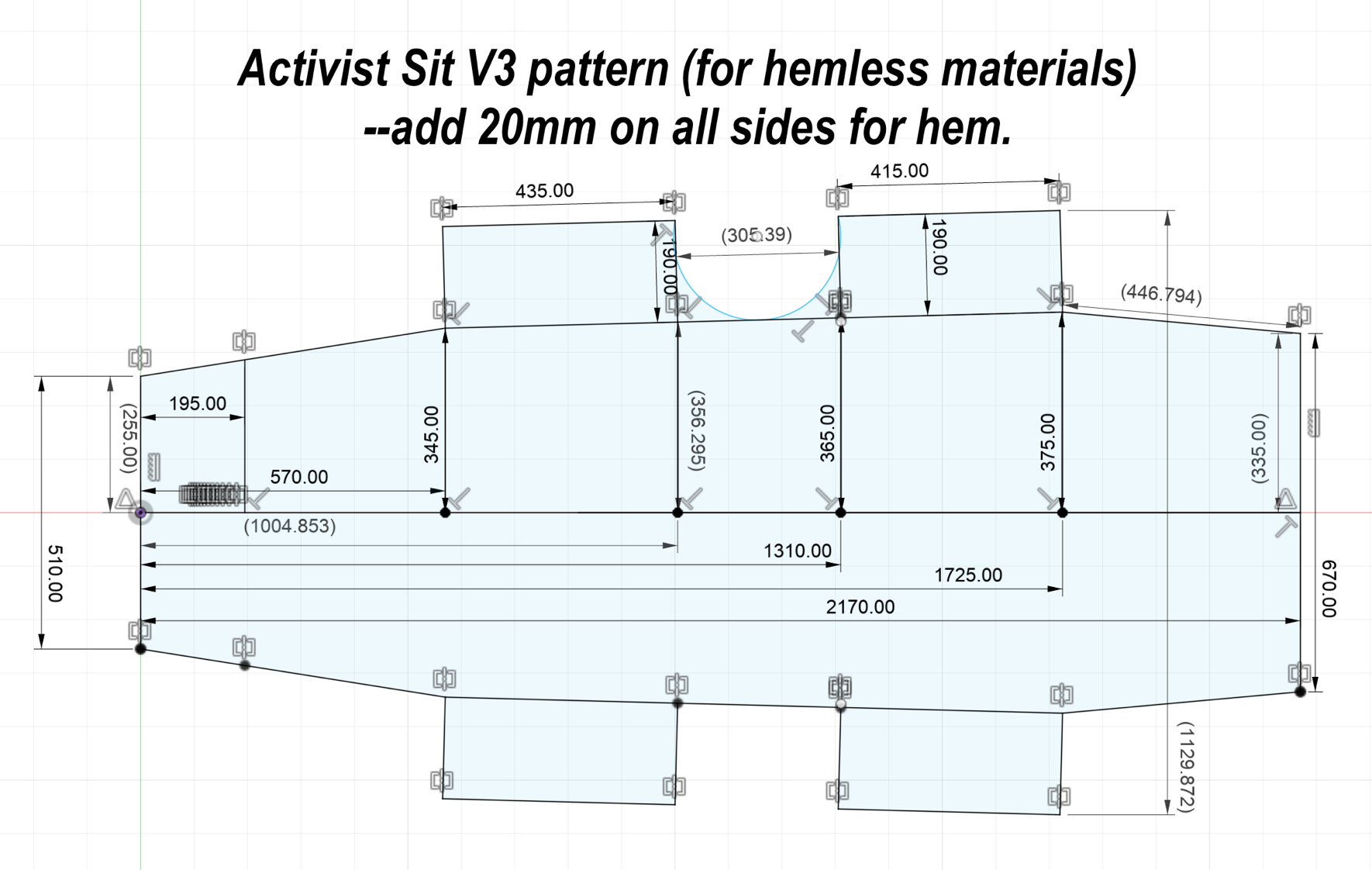

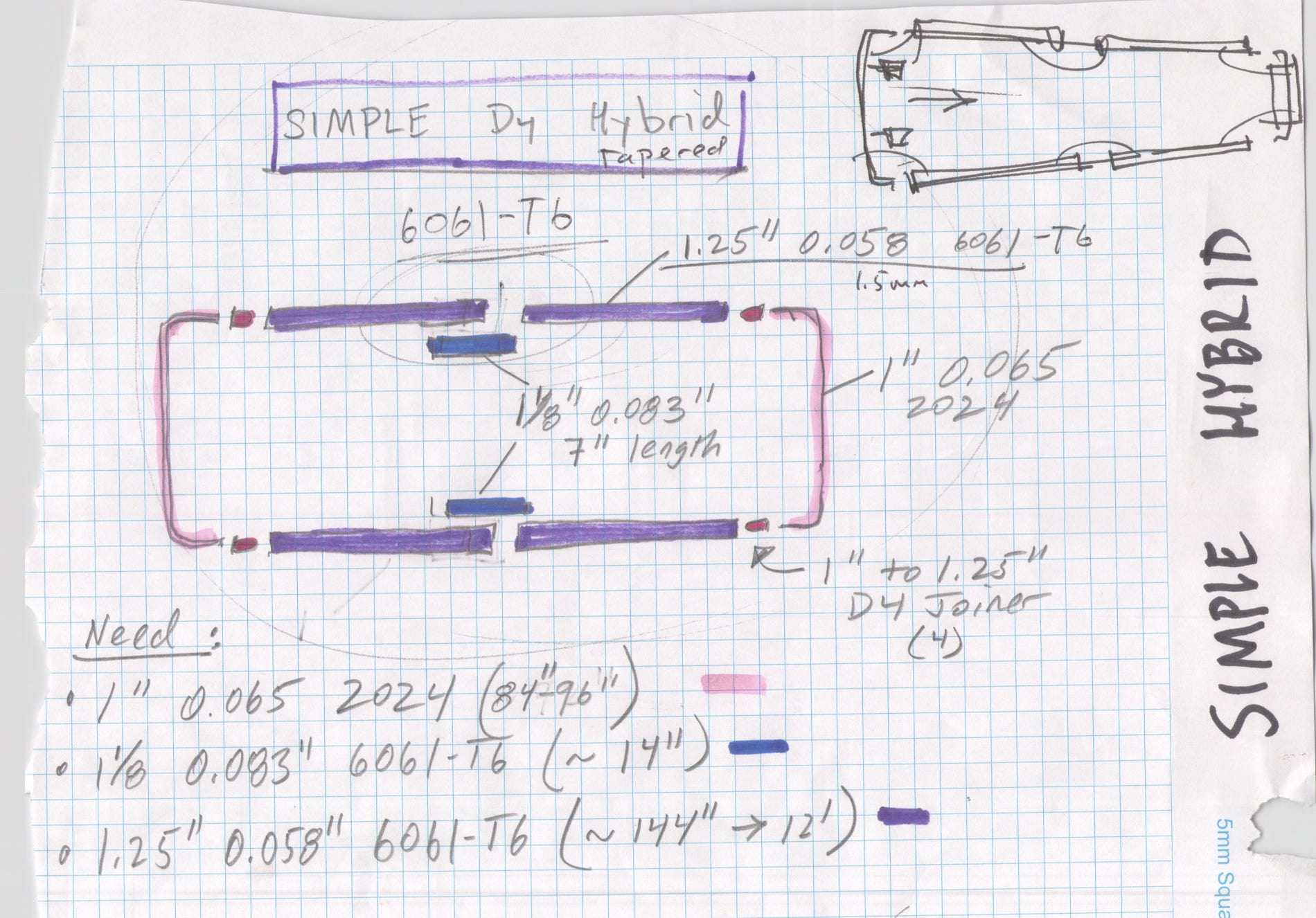

TUBING:

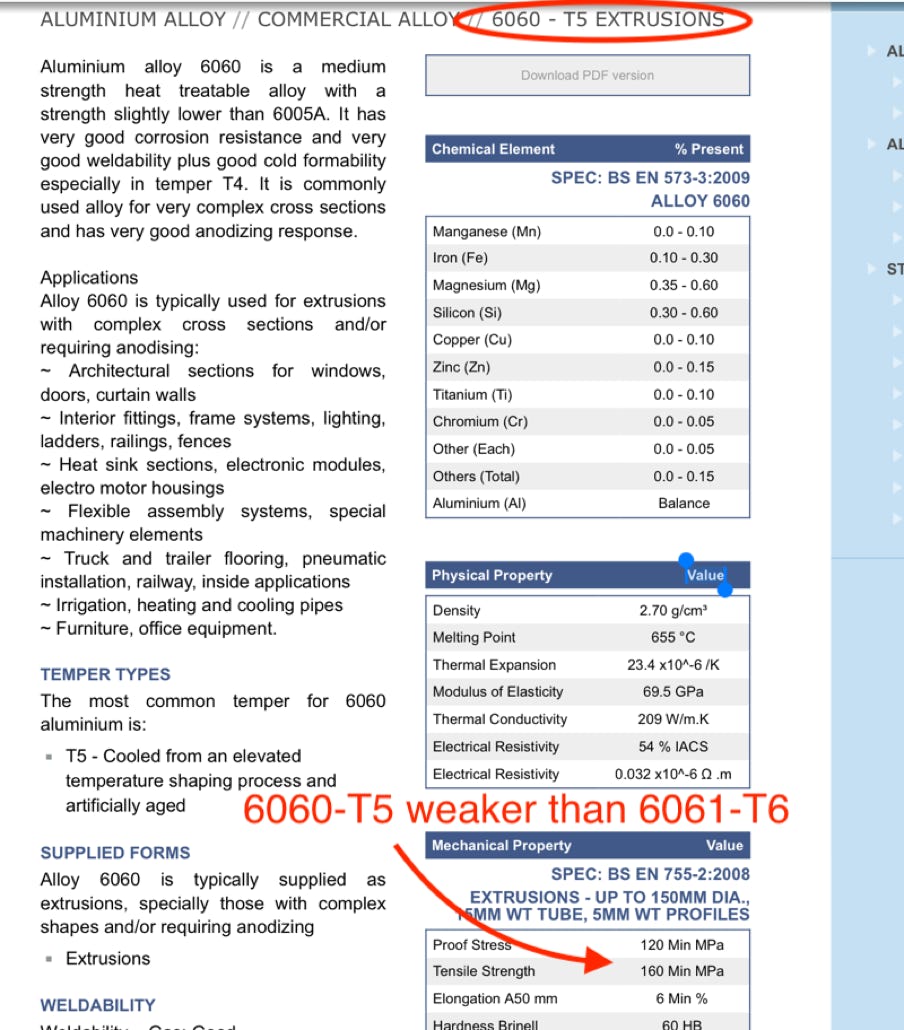

The standard tubing for a lightweight portaledge frame is 6061-T6 Aluminum Tubing. SEE THIS PAGE FIRST.

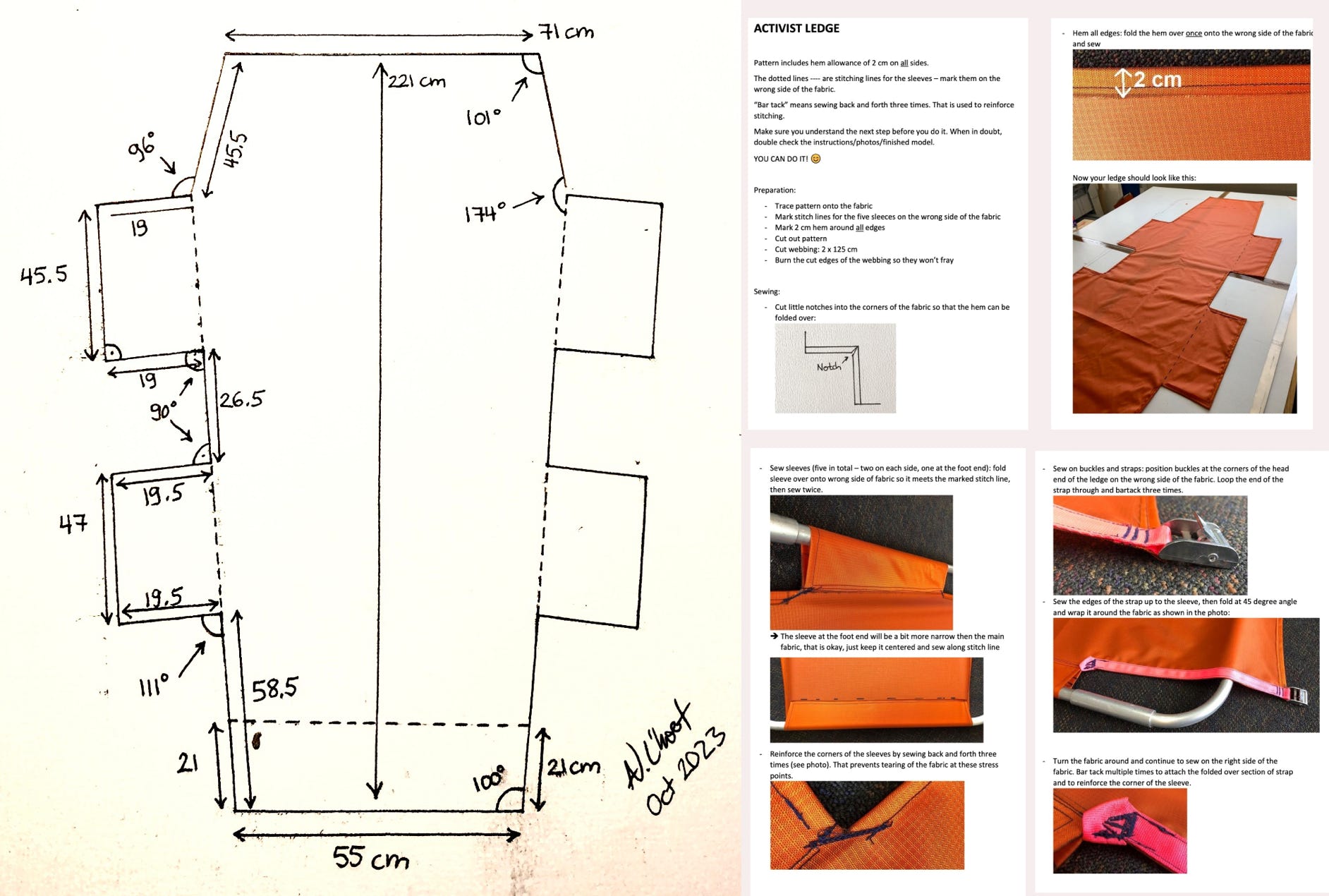

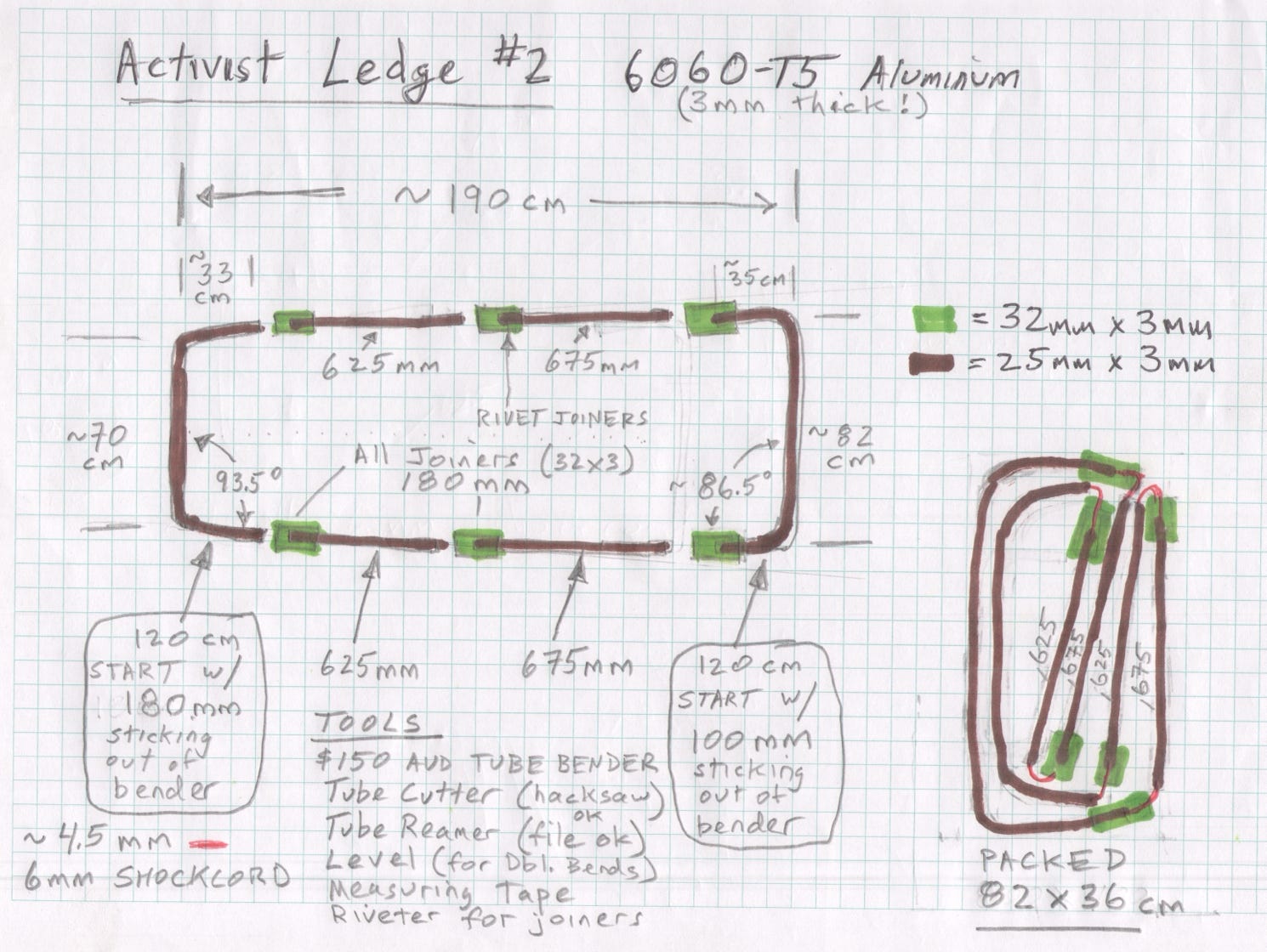

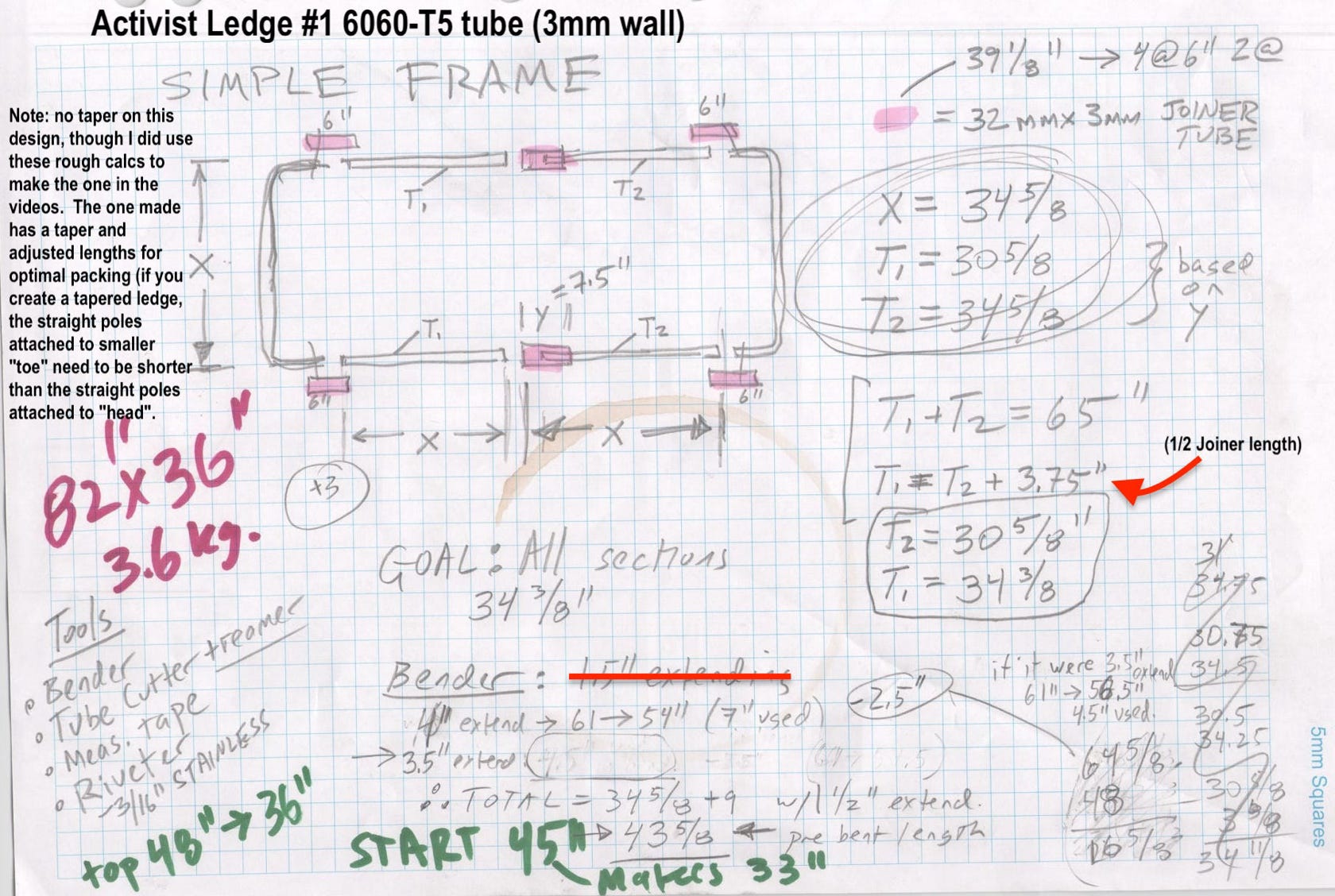

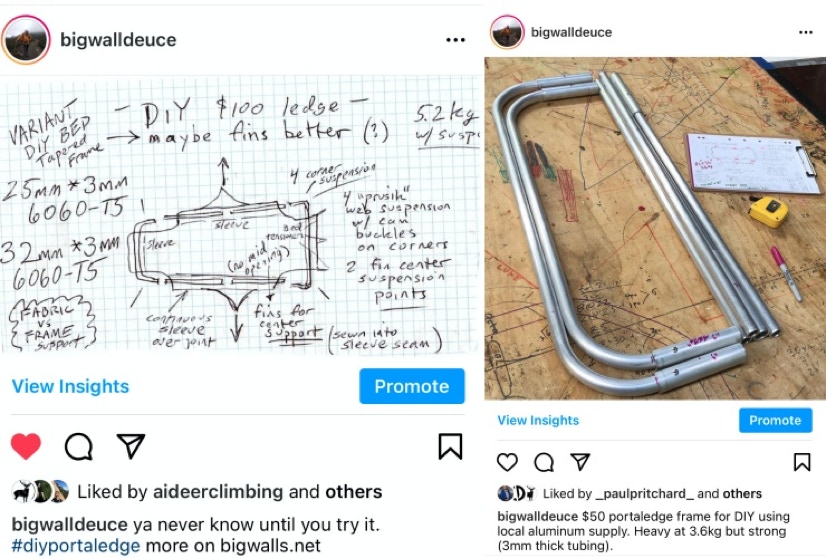

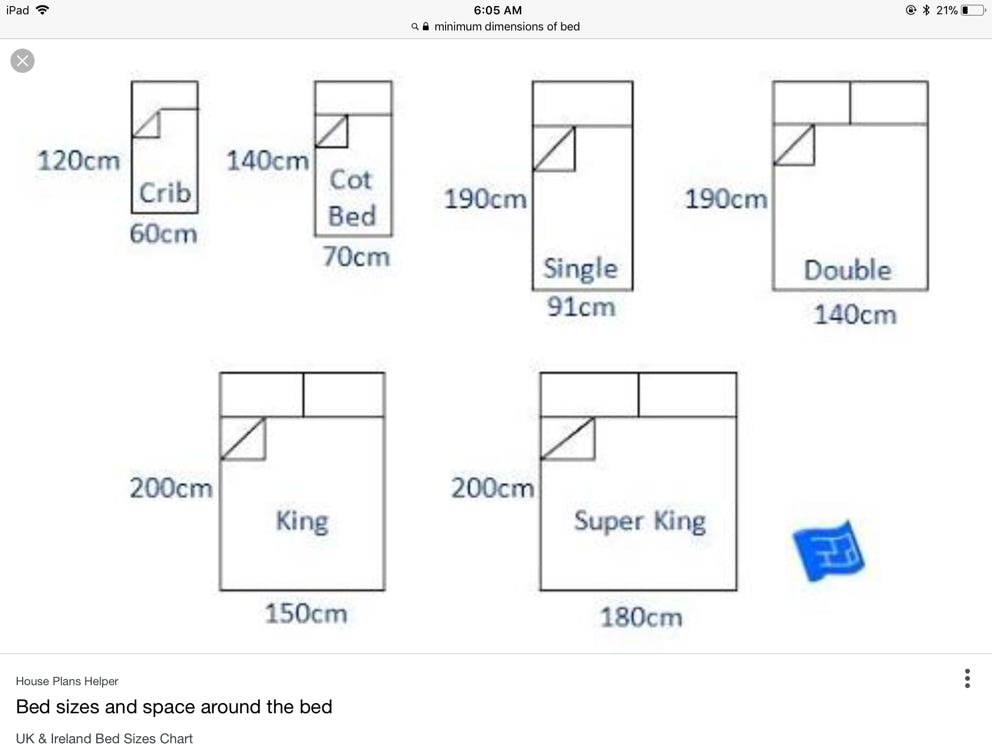

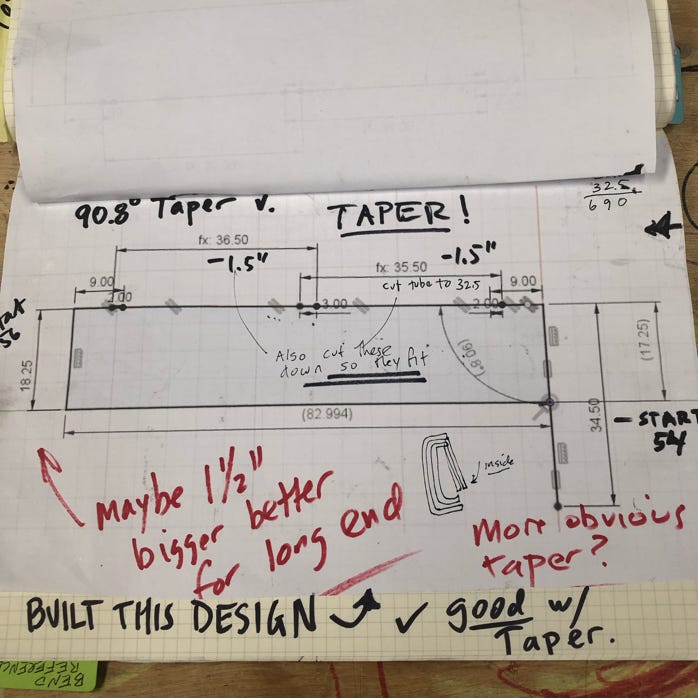

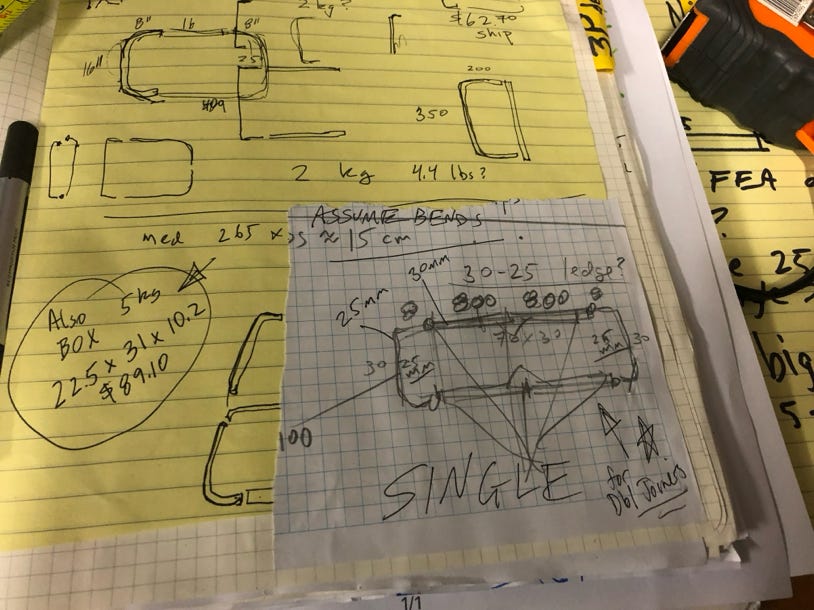

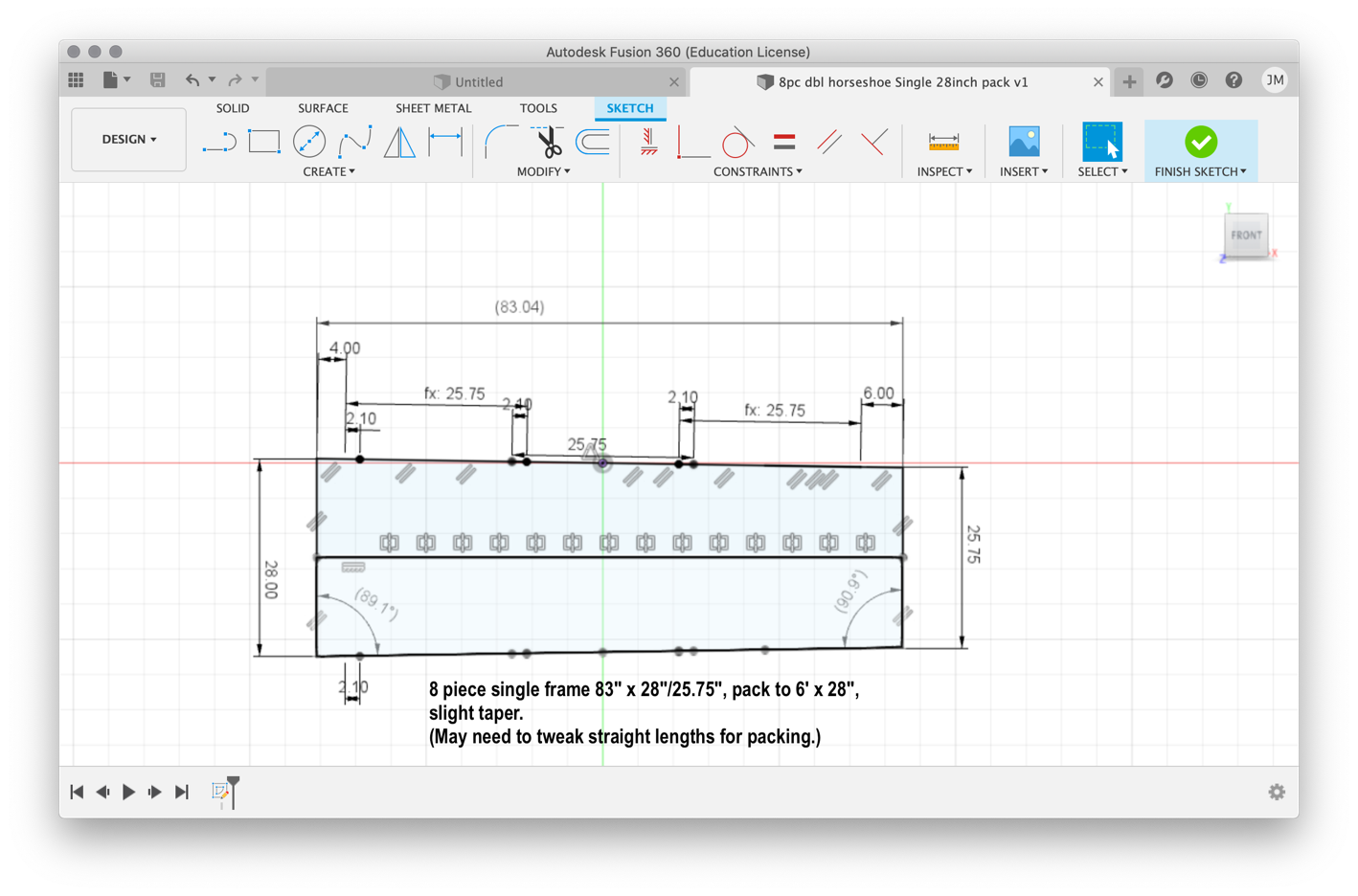

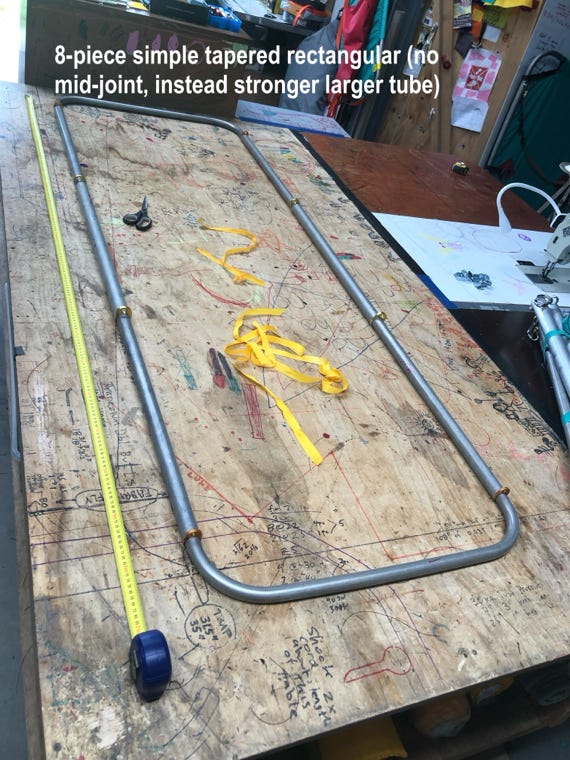

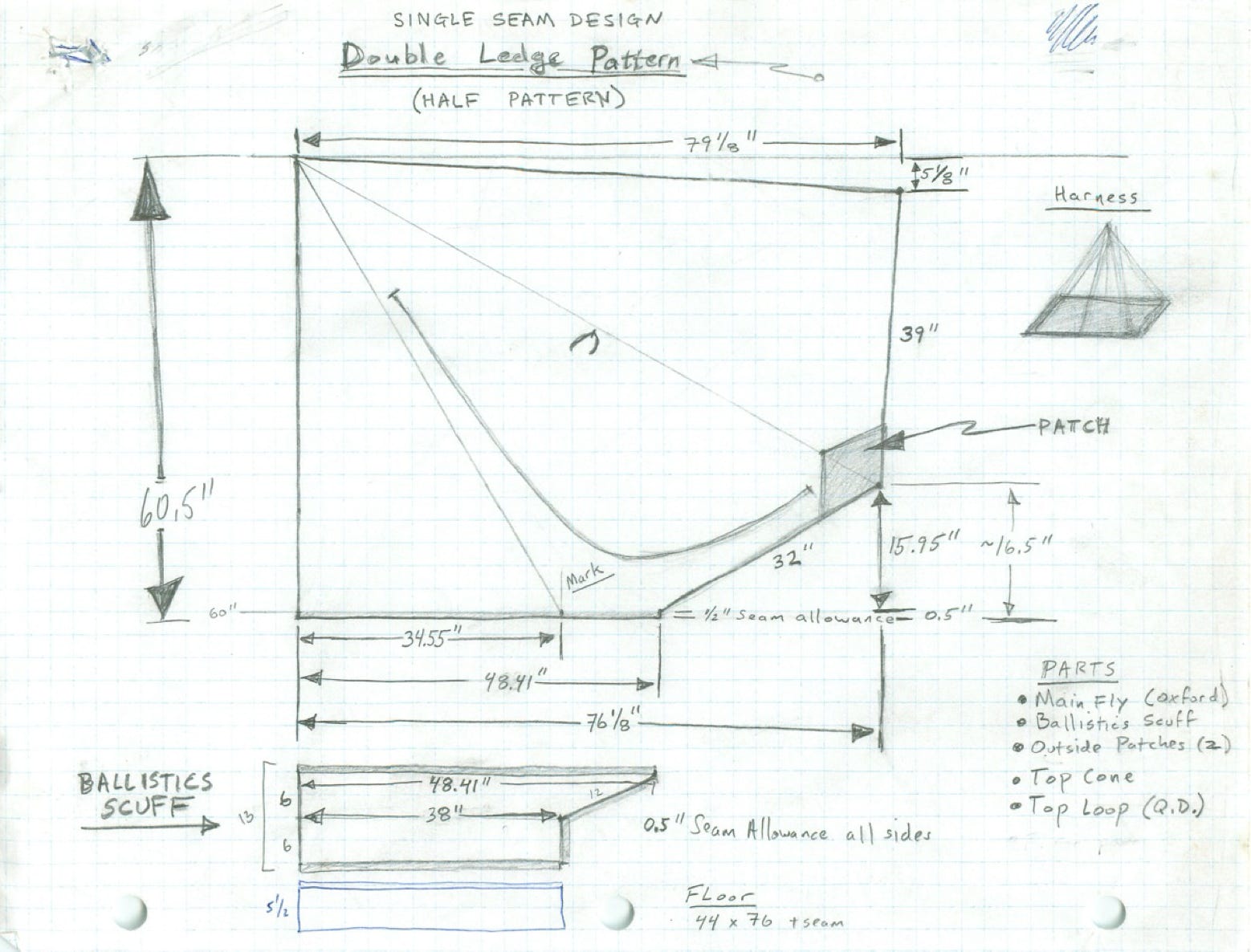

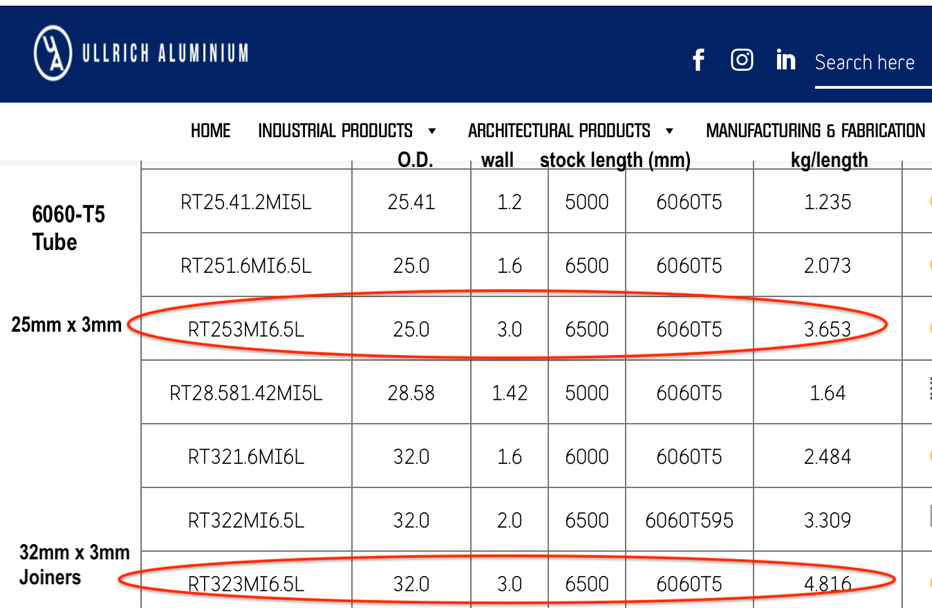

USING LOWER GRADE TUBING: If you cannot get 6061-T6 or better, you can use local sourced 6000 series aluminum if you beef up the wall thickness to about 1/8" (twice as thick as high grade aluminum design). For example, below is a stock list of the commonly found 6060-T5 aluminum tube you can buy at a number of supply shops locally in Australia. It is important to note that 6060-T5 is a softer and weaker grade than 6061-T6 and thus important to overdesign the frame with heavier thicker tube. 6060-T5 would NOT be recommended for advanced designs such as 2-person ledges or the new D4 “cantilever” designs, as there are more stresses involved with these designs, and requires a higher strength tube. This tube should only be used with smaller, one-person traditional side-to-wall portaledges and used with care. A compact one-person frame will be around 2 kg heavier than an equivalently sturdy 6061-T6 frame. If using the lower grade aluminum, such as 6060-T5, increase the wall thickness to at least 3mm. Maximum recommended size: 1.9m x 0.85m. TEST BEFORE USING IN ANY VERTICAL SITUATION.

Link opens YouTube video of Lisa Searle explaining the southern forest blockade and use of Activist Sit:

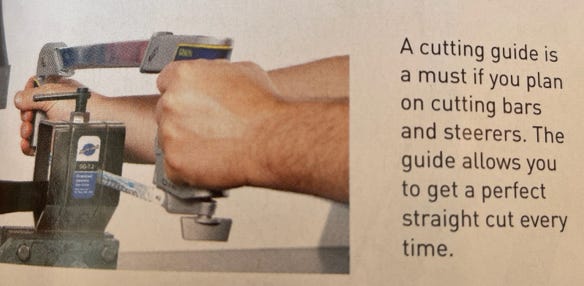

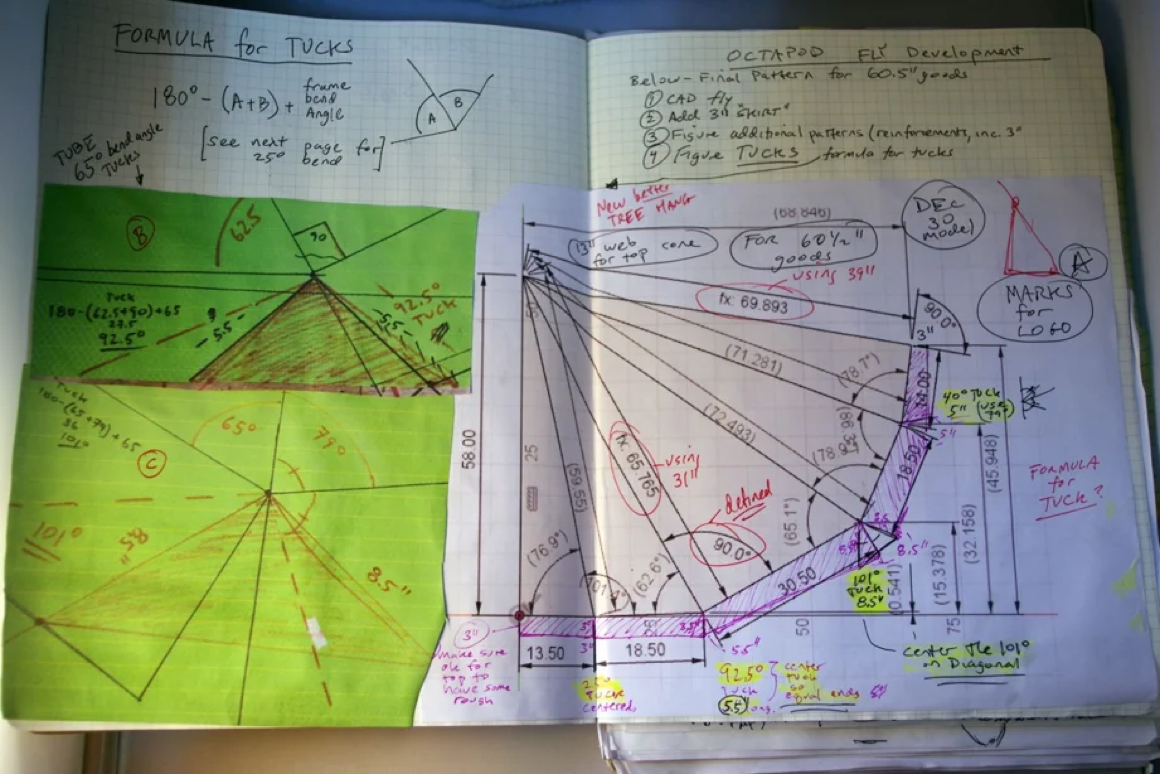

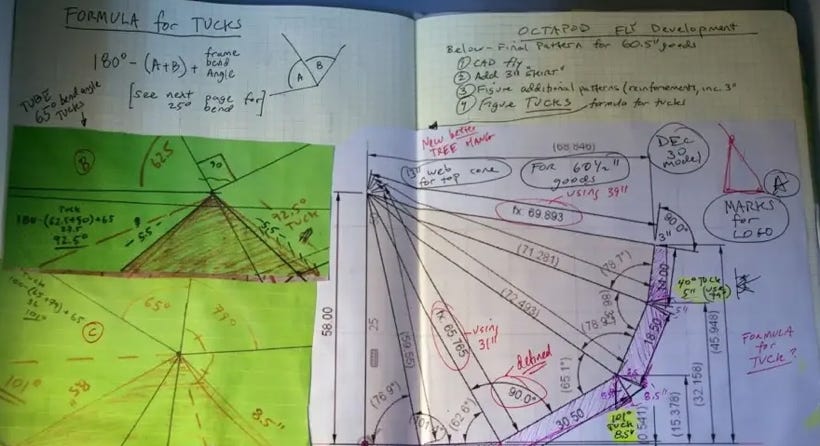

BENDING TUBE—USE PROPER TOOL AND RADIUS.

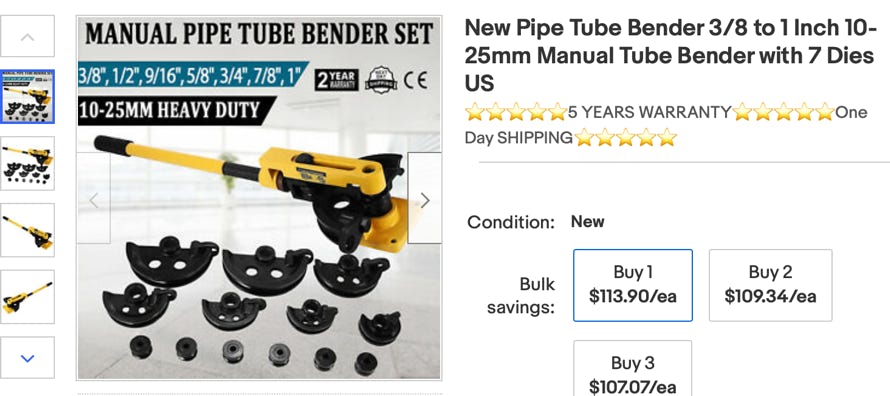

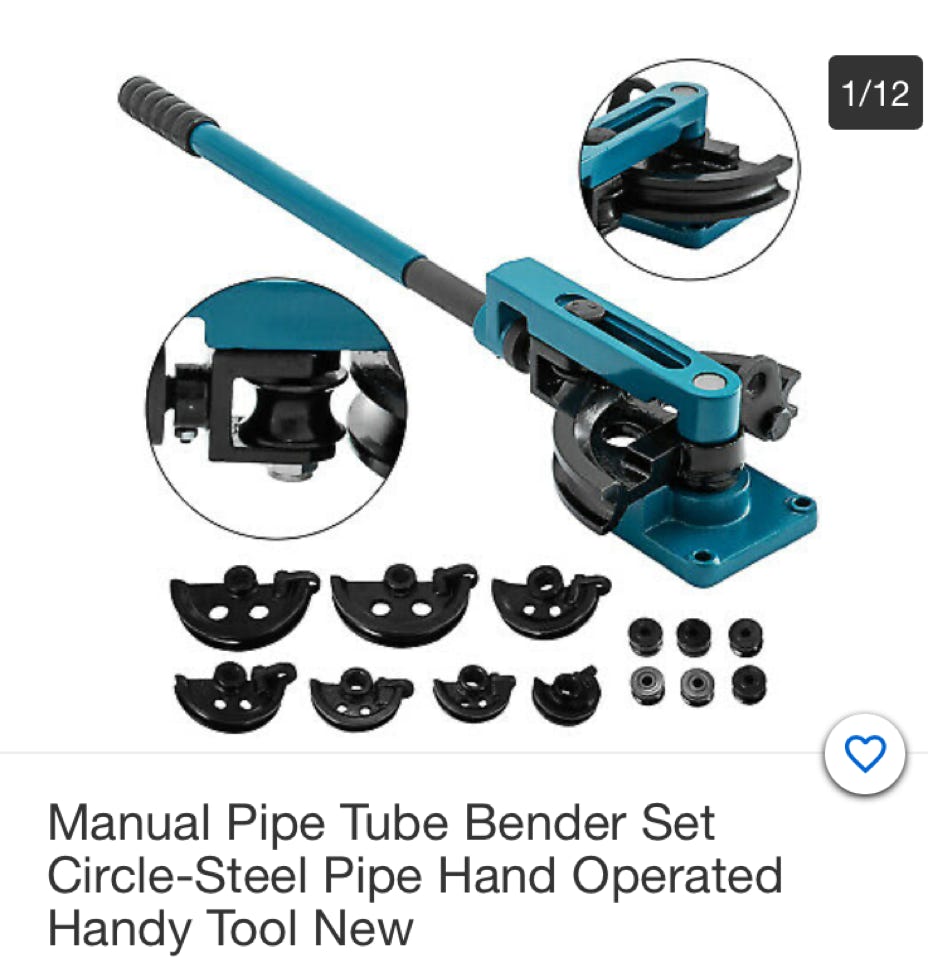

There are a myriad of tools used to bend tubing. Some people have made their own tube benders. The most affordable option getting a tool that allows fine control and with the correct bending radius is a tool currently found on eBay for less than $120USD. Look for the W-25S as pictured below (bends up to 1" so if you are building with high strength tubing, this bender also suitable for high grade single ledges using 1” 0.065” 2024-T3 tube.

(NOTE: NOT PIPE BENDERS, pipe is a different category of hollow rounds. Pipe benders are not suitable for thin wall tube bending).

IMPORTANT! MAKE SURE YOUR JOINER TUBES ARE STRONGER THAN THE MAIN TUBE. The joint is the weakest link, so the tube needs to be at least as strong as the main tube. For example, if you wanted to use 25mm 6060-t5 “inside joiner” with 32mm x 3mm 6060-T5 tube, the wall thickness would need to be greater than 3mm, which is harder to find in a mid-grade aluminum. Alternatively, you could use a good 4130 steel 25mm/1” tube for a joiner, at least 1.2mm thick (do not use a lower grade material for joiners—the joiner tube needs to be the strongest tube in the ledge!).